Producing biodegradable plastics without using conventional plastics is gaining importance due to several environmental and sustainability reasons. Here are some key reasons why this shift is so crucial:

Conventional plastics, primarily derived from fossil fuels, persist in the environment for hundreds of years, causing widespread pollution and harming precious ecosystems. Innonxt Biodegradable plastics, on the other hand, naturally break down faster, lightening our Earth’s burden.

Biodegradable plastics offer a solution to the growing problem of plastic waste. They can be broken down into harmless substances, shrinking the piles of plastic waste that clutter landfills, oceans, and the homes of our wildlife friends.

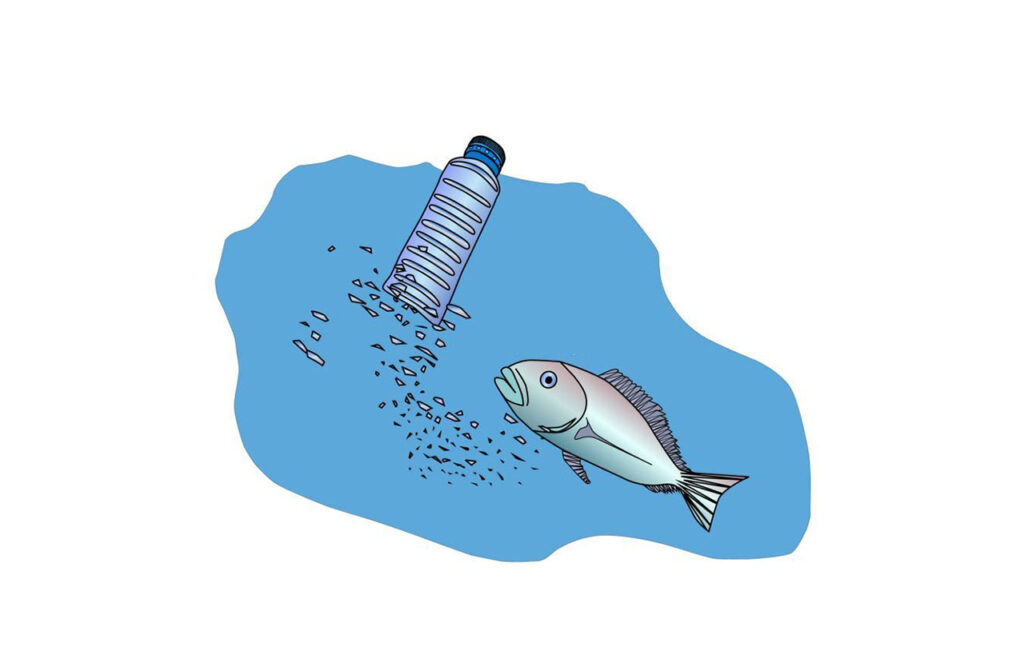

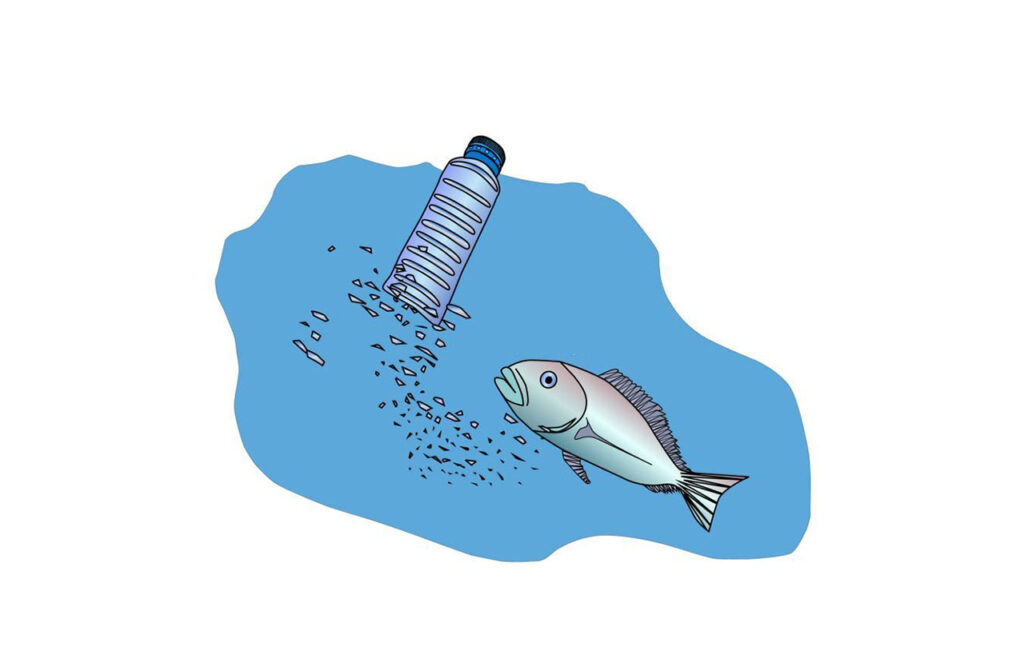

Conventional plastics break into tiny, harmful microplastics, infiltrating our soil and waters, threatening wildlife and even our food chain. Whereas Innonxt Biodegradable plastics break down into smaller, zero harmful particles and decompose completely, removing the risk of microplastic pollution.

Many biodegradable plastics are derived from renewable resources, such as corn starch or sugarcane, which have a lower carbon footprint compared to fossil-based plastics. This helps us battle the greenhouse gases associated with conventional plastic production.

Biodegradable plastics can be made from agricultural waste and other sustainable sources, reducing the reliance on fossil fuels and promoting a more sustainable and circular economy.

Our biodegradable plastics are suitable for medical applications because they are biocompatible and can be safely absorbed by the human body. This can reduce the need for additional surgeries to remove implants.

Our quest for biodegradable plastics has driven research and innovation in materials science. This has led to development of our novel Innonxt Biodegradable plastics with diverse properties, such as flexibility, strength, and durability, making them suitable for Biodegradable Plastics plastics with diverse properties, such as flexibility, strength, and durability, making them suitable for various applications at par with conventional plastics.

Increasing awareness about the environmental impacts of conventional plastics has led to greater consumer demand for sustainable alternatives. Companies that invest in biodegradable plastics are gaining a competitive edge in the markets.

Innonxt Biodegradable plastics can help protect ecosystems and wildlife by completely eliminating the harmful effects of plastic pollution. This, in turn, supports biodiversity and the health of our planet.

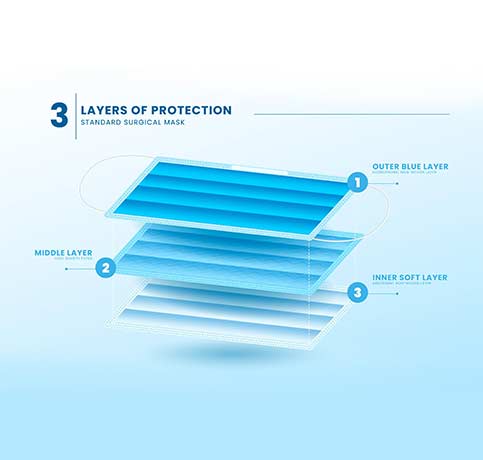

• Traditional single-use masks are typically made from non-biodegradable materials like polypropylene, which can take hundreds of years to decompose. When these masks are improperly disposed of or end up in the environment, they contribute to plastic pollution. Innonxt Biodegradable masks, on the other hand, break down more quickly and do not choke off our environment.

• The production of Innonxt Biodegradable masks often involves less energy and resources compared to traditional masks. This can result in a lower carbon footprint, helping to mitigate climate change.

• Innonxt Biodegradable masks can be composted, which means they do not need to be sent to landfills, where they can take up valuable space and release methane, a potent greenhouse gas. It decomposes completely in a set number of days without leaving any residue. For example; If the plastic is set to decompose after 180 days, it’ll begin to decompose completely. Innonxt’s patented biodegradable plastics have a unique feature for customising the time period for decomposition.

• Traditional single-use masks are typically made from non-biodegradable materials like polypropylene, which can take hundreds of years to decompose. When these masks are improperly disposed of or end up in the environment, they contribute to plastic pollution. Innonxt Biodegradable masks, on the other hand, break down more quickly and do not choke off our environment.

• The production of Innonxt Biodegradable masks often involves less energy and resources compared to traditional masks. This can result in a lower carbon footprint, helping to mitigate climate change.

• Innonxt Biodegradable masks can be composted, which means they do not need to be sent to landfills, where they can take up valuable space and release methane, a potent greenhouse gas. It decomposes completely in a set number of days without leaving any residue. For example; If the plastic is set to decompose after 180 days, it’ll begin to decompose completely. Innonxt’s patented biodegradable plastics have a unique feature for customising the time period for decomposition.

“Since the 1970s, the rate of plastic production has grown faster than that of any other material. Global plastic production exceeds 400 million metric tonnes annually. If historic growth trends continue, global production of primary plastic is forecasted to reach 1,100 million tonnes by 2050. We have also seen a worrying shift towards single-use plastic products.

Approximately 36 per cent of all plastics produced are used in packaging, including single-use plastic products for food and beverage containers, approximately 85 per cent of which ends up in landfills or as unregulated waste.

Additionally, some 98 per cent of single-use plastic products are produced from fossil fuel, or “virgin” feedstock. The level of greenhouse gas emissions associated with the production, use and disposal of conventional fossil fuel-based plastics is forecast to grow to 19 per cent of the global carbon budget by

2040.” – UNEP

Medical

Approximately 36 per cent of all plastics produced are used in packaging, including single-use plastic products for food and beverage containers, approximately 85 per cent of which ends up in landfills or as unregulated waste.

By adopting our innovative Biodegradable plastics, you can contribute greatly towards environment and sustain your business for the future. Because, the whole world is switching towards safe plastics and Innonxt Biodegradable plastics are at the forefront of this transition.